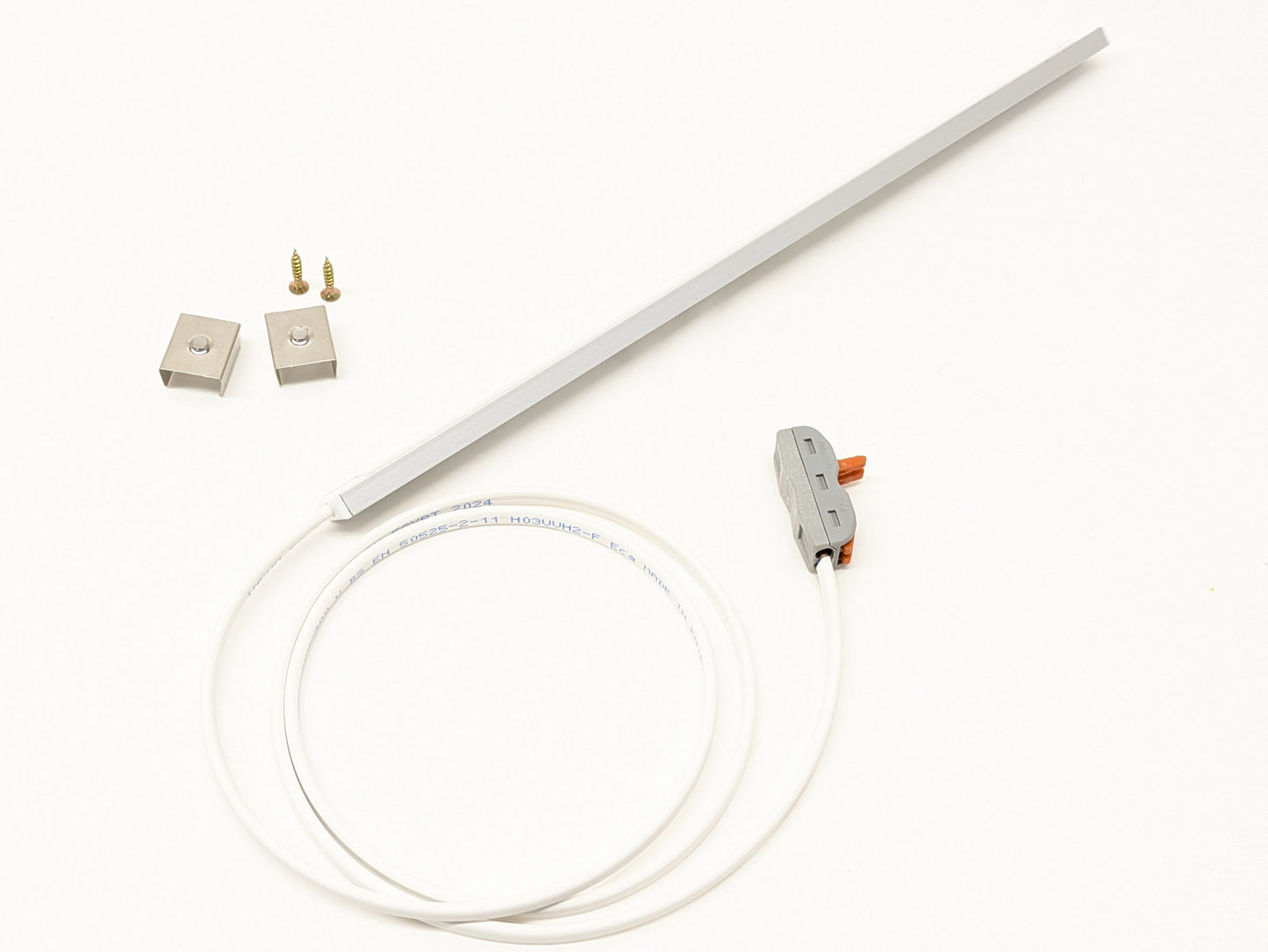

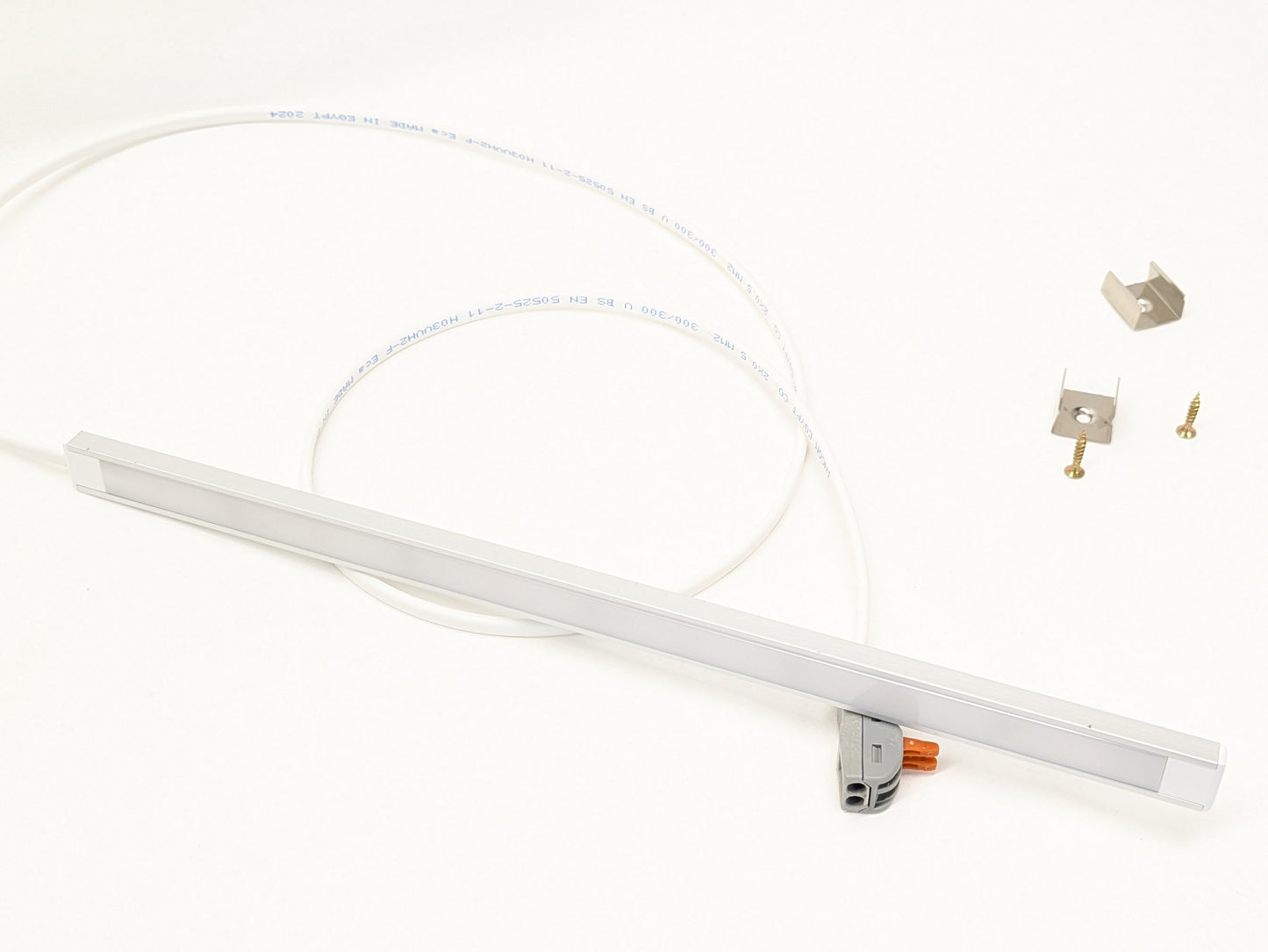

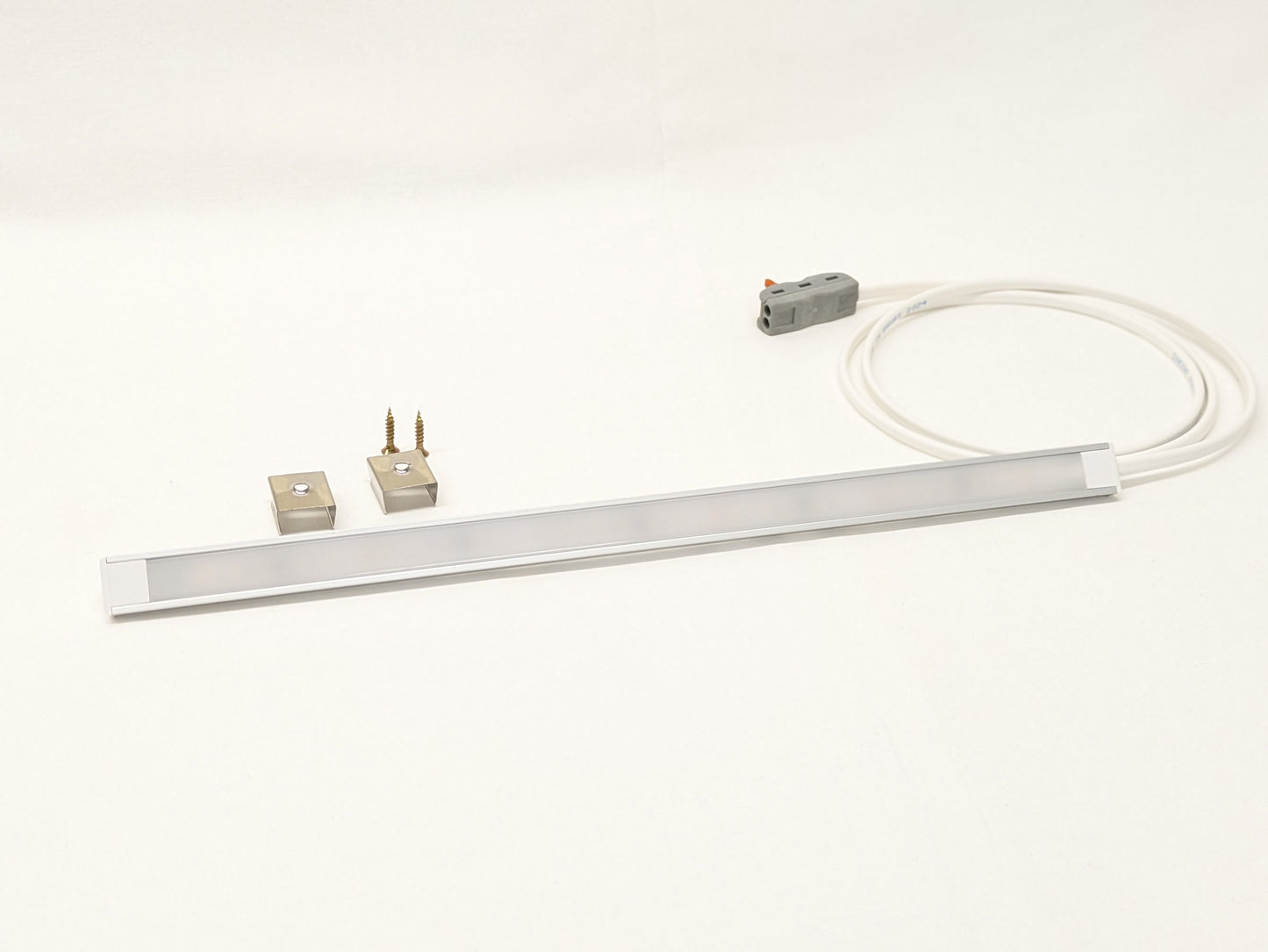

Under cupboard lighting has become a popular and practical choice for modern kitchens. It provides essential illumination for tasks, enhances the aesthetic appeal, and creates a warm and inviting atmosphere. LED strips are a favored option for this purpose due to their energy efficiency, flexibility, and ease of installation. However, a common mistake is to install LED strips without using aluminum channels. Here’s why this can be problematic.

Heat Dissipation

LED strips generate heat during operation. When installed under cupboards, the confined space can exacerbate heat buildup. Without aluminum channels, which act as heat sinks, the accumulated heat can:

- Reduce Efficiency: Excess heat can decrease the light output of LEDs, making them less effective.

- Shorten Lifespan: Prolonged exposure to high temperatures can significantly reduce the lifespan of LED strips, leading to premature failure.

- Potential Damage: In extreme cases, the lack of adequate heat dissipation can cause the strips to overheat and become damaged.

Aluminum channels dissipate heat efficiently, ensuring that your under cupboard lighting remains bright and lasts longer.

Protection

Kitchens are environments where dust, grease, and moisture are prevalent. Unprotected LED strips can quickly accumulate grime, which can:

- Reduce Light Quality: Dust and grease on the strips can diminish their brightness and alter the color of the light.

- Cause Electrical Issues: Moisture can infiltrate the LED strips, potentially causing short circuits and electrical failures.

- Physical Damage: Bare LED strips are vulnerable to physical damage from accidental knocks and bumps.

Aluminum channels provide a protective barrier against these elements, keeping the LED strips clean and functional.

Aesthetic Appeal

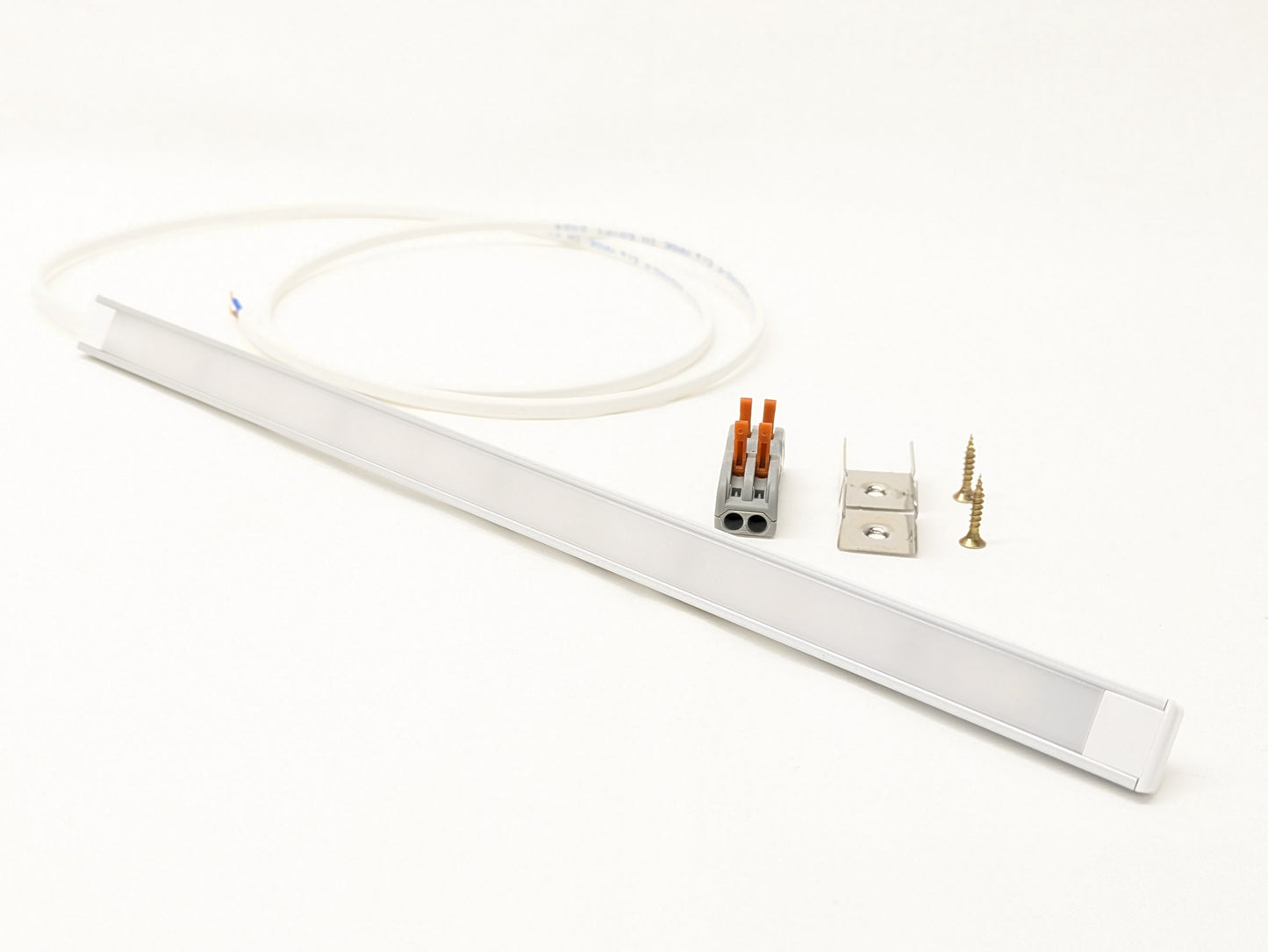

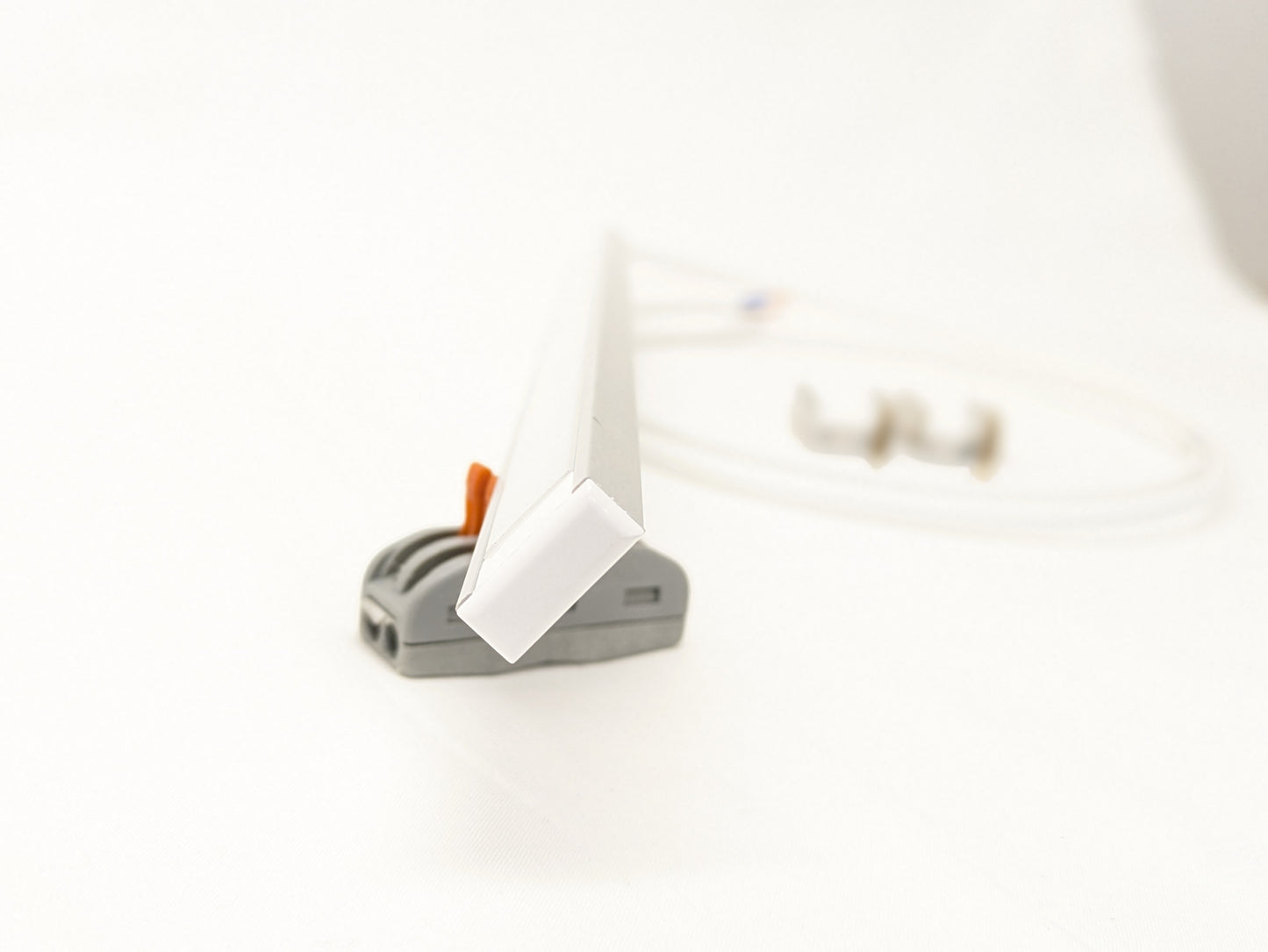

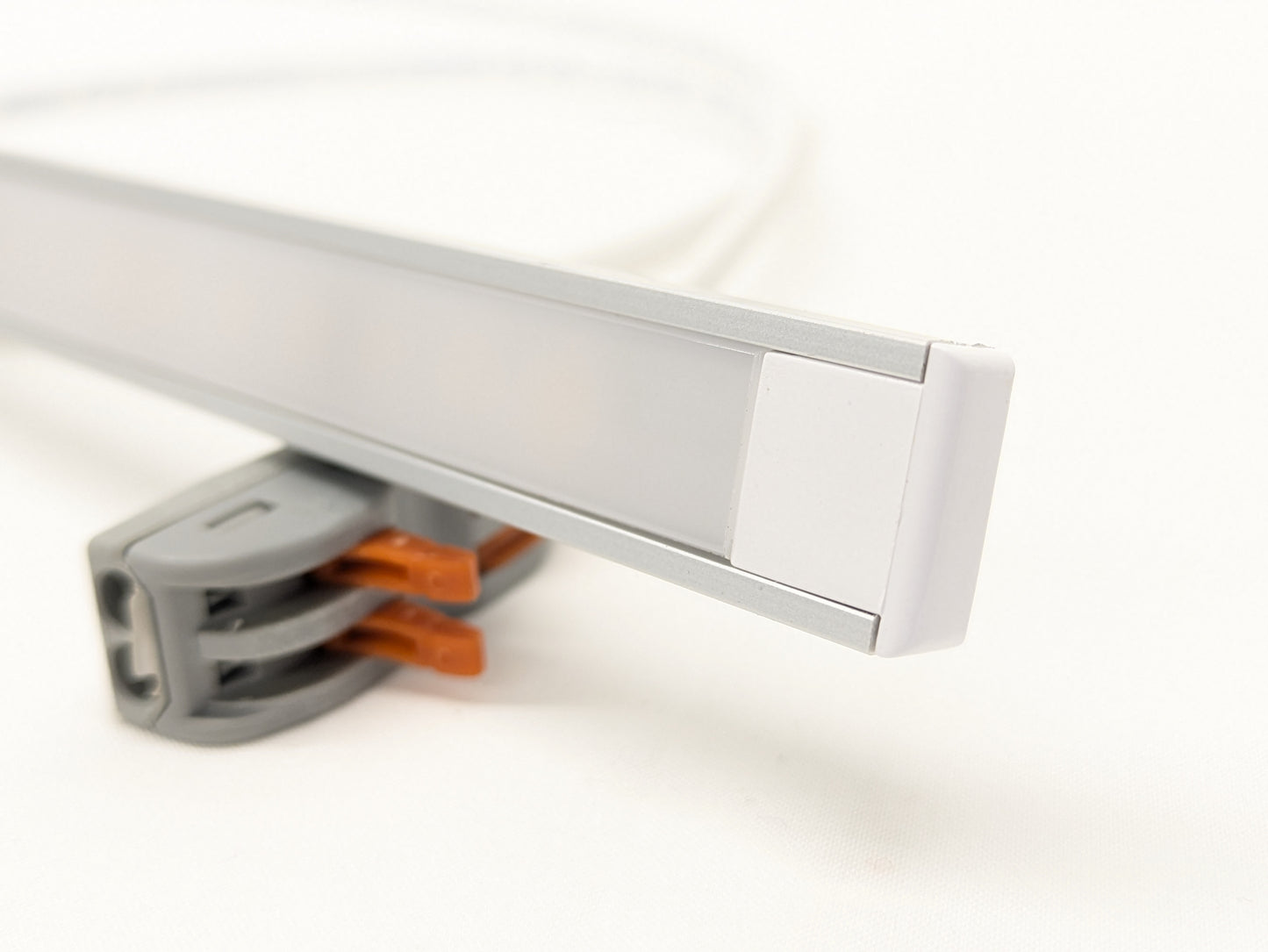

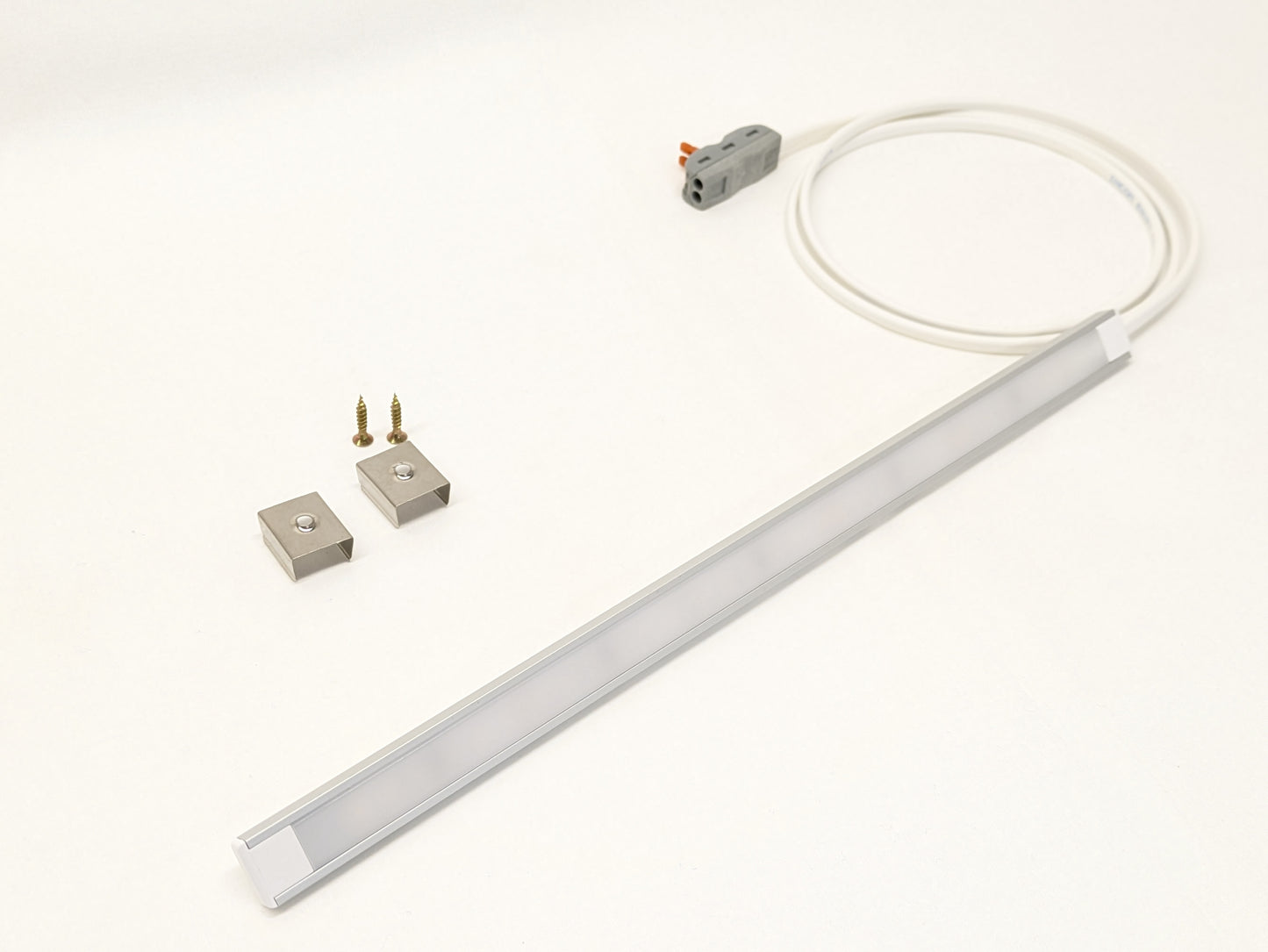

Under cupboard lighting is not just functional but also an important design element in your kitchen. Bare LED strips can look unsightly and unfinished. In contrast, aluminum channels:

- Enhance Appearance: They offer a sleek, professional finish that complements modern kitchen designs.

- Conceal Imperfections: Aluminum channels can hide the wiring and mounting hardware, resulting in a cleaner look.

- Even Light Distribution: Many aluminum channels come with diffusers that spread the light evenly, eliminating hotspots and creating a smooth, continuous line of light.

Installation Ease

Mounting LED strips directly under cupboards can be challenging. Without aluminum channels:

- Adhesion Issues: The adhesive backing of LED strips may not stick well to certain surfaces, especially if they are greasy or uneven.

- Alignment Problems: Keeping the strips straight and properly aligned can be difficult, leading to a less professional look.

Aluminum channels provide a secure and reliable mounting solution. They simplify the installation process and ensure the strips remain in place over time.

Durability

Adhesive-backed LED strips can lose their stickiness over time, especially in a kitchen environment. This can result in:

- Sagging: Strips may come loose and sag, affecting both their appearance and functionality.

- Frequent Replacements: Without a durable mounting solution, you might find yourself frequently reattaching or replacing the LED strips.

Aluminum channels offer a robust and lasting mounting option, reducing the need for maintenance and replacements.

Conclusion

For effective, durable, and aesthetically pleasing under cupboard lighting, using aluminum channels with your LED strips is essential. They provide superior heat dissipation, protection from kitchen elements, a polished appearance, easier installation, and greater durability. By investing in aluminum channels, you ensure that your under cupboard lighting remains bright, beautiful, and long-lasting, enhancing both the functionality and style of your kitchen.